Resources

Products

Single Ply Commercial Roofing

Bituminous Commercial Roofing

EPDM Roofing Systems

With superior durability and flexibility, EPDM is a smart roofing solution.

Our EPDM production facility is one of the world's most technologically advanced, allowing us to extrude our sheets instead of using the traditional calendering process.

Our EPDM is manufactured thicker with a more uniform surface finish. This advancement in manufacturing cleaner sheets requires less preparation to ensure a stronger bond during installation.

JM EPDM NR

Membrane: Nonreinforced, cured EPDM (ethylene propylene diene monomer).

Fully Extruded: Produces fewer air voids, more uniform thickness and smoother sheets.

Vulcanization Process: Combines two layers of membrane to produce a fully cross-linked monolithic membrane.

Membrane Formulation: Performs in extreme temperature climates and withstands differential movement (elongation).

UV-Stabilization Properties: Offers outstanding ozone and weather resistance delivering one of the longest service lives available.

Technical Expertise: Backed by 30+ years of EPDM experience and installations.

Installation Guides

JM EPDM Application Guide

JM Vapor Barrier SA Installation Guide

System Considerations

Re-roofing

Roof Decks

Vapor Retarders - SA Primer

Vapor Retarders - SA Primer Low VOC

JM EPDM R

Meets the requirements of ASTM D 4637, Type II

Membrane: Cured EPDM (ethylene propylene diene monomer) reinforced with a tough 1,000+ denier polyester mat.

Fully Extruded: Produces fewer air voids, more uniform thickness and smoother sheets.

Vulcanization Process: Produces a redundant waterproofing monolithic membrane.

Polymer Formulation: Performs in extreme temperature climates and withstands differential movement.

UV-Stabilization Properties: Offers superior ozone and weather resistance delivering one of the longest service lives available.

Technical Expertise: Backed by 30+ years of EPDM experience and installations

Colors: Black

Installation Guides

JM EPDM Application Guide

JM Vapor Barrier SA Installation Guide

System Considerations

Re-roofing

Roof Decks

Vapor Retarders - SA Primer

Vapor Retarders - SA Primer Low VOC

JM EPDM NR FIT Systems

Meets the requirements of ASTM D 4637, Type I

Membrane: Nonreinforced, cured EPDM (ethylene propylene diene monomer).

Factory Inseam Tape: For superior quality assurance and labor savings compared to field fabricated seams.

Fully Extruded: Produces fewer air voids, more uniform thickness and smoother sheets.

Vulcanization Process: Combines two layers of membrane to produce a fully cross-linked monolithic membrane.

Membrane Formulation: Performs in extreme temperature climates and withstands differential movement (elongation).

UV-Stabilization Properties: Offers outstanding ozone and weather resistance delivering one of the longest service lives available.

Technical Expertise: Backed by 30+ years of EPDM experience and installations.

Installation Guides

JM Vapor Barrier SA Installation Guide

JM Vapor Barrier SA Installation Guide

EPDM R FIT (MF) install guide

System Considerations

Re-roofing

Roof Decks

Vapor Retarders - SA Primer

Vapor Retarders - SA Primer Low VOC

JM EPDM R FIT Systems

Meets the requirements of ASTM D 4637, Type II

Membrane: Cured EPDM (ethylene propylene diene monomer) reinforced with a tough 1,000+ denier polyester mat. Excellent puncture and hail resistance.

Factory Inseam Tape: For superior quality assurance and labor savings compared to field fabricated seams.

Fully Extruded: Produces fewer air voids, more uniform thickness and smoother sheets.

Vulcanization Process: Combines two layers of membrane to produce a fully cross-linked monolithic membrane.

Polymer Formulation: Performs in extreme temperature climates and withstands differential movement (elongation).

UV-Stabilization Properties: Offers outstanding ozone and weather resistance delivering one of the longest service lives available.

Technical Expertise: Backed by 30+ years of EPDM experience and installations.

Installation Guides

JM EPDM Application Guide

JM Vapor Barrier SA Installation Guide

EPDM R FIT (MF) install guide

System Considerations

Re-roofing

Roof Decks

Vapor Retarders - SA Primer

Vapor Retarders - SA Primer Low VOC

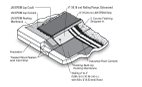

JM Vapor Barrier SA

Tri-laminate woven polyethylene, nonslip, UV-protected top surface: Provides temporary weather protection for 90 days. Provides high tensile strength and puncture resistance.

Self-sealing, high-quality SBS rubber and asphalt blend: Provides low air and vapor permeability.

Silicone release film: Allows for ease of self-adhering installation.

Installation Guides

JM Vapor Barrier SAR

Tri-laminate woven polyethylene, nonslip, UV-protected top surface: Provides temporary weather protection for 90 days. Provides high tensile strength and puncture resistance.

Self-adhering modified bitumen: Self-sealing, high-quality SBS rubber and asphalt blend: provides low air and vapor permeability.

Split-back silicone release film: Easy-to-peel release film sheet that allows for ease of self-adhering installation.

Installation Guides

JM EPDM Metal/Membrane Flashing

JM EPDM Metal/Membrane Flashing is a specially designed and manufactured flashing for sealing and waterproofing JM EPDM roofing systems where they join an adjacent bituminous roof membrane. It is comprised of a nominal 6" (15.24 cm) strip of JM EPDM membrane secured (using a patented method) to flanges of nominal 4" (10.16 cm) wide, Type 100G-6, galvanized steel.

JM 3oz Polyester Slipsheet

Use: JM 3 oz Polyester Slipsheet is intended for use as a separation layer between an existing roof system and a new single ply recover system.

Material: 3.0 oz/yd2 (102 g/m2 ) needle-punched, non UV-resistant polyester fabric.

Color: White

JM EPDM 10 Inch Reinforced Perimeter Strip

JM EPDM 10” RPS (Reinforced Perimeter Strip) is a 10" (25.4 cm) wide, 45 mil (1.14 mm) thick, polyester scrim reinforced, cured EPDM strip with a factory-laminated, 3" (7.62 cm) self-adhering seam tape along each edge. It is used to secure EPDM membrane from underneath in perimeters and corners and as additional securement as specified in Johns Manville specifications and details. Also consider using with the JM EPDM Peel & Stick 6" RTS (Reinforced Termination Strip) as part of a comprehensive peel & stick perimeter reinforcement system.

JM EPDM Peel and Stick Flashing

JM EPDM Peel & Stick Flashing is a 6", 9", and 12" (30.48 cm) wide, uncured EPDM (ethylene propylene diene monomer) sheet with a diamond texture on the top side with a release liner and a factory laminated, self-adhering EPDM/butyl tape. This product is formulated to provide high initial strength in both peel and shear at typical rooftop temperatures. It also improves the speed and quality of flashings on JM EPDM roofing systems.

JM EPDM Peel and Stick Inside/Outside Corners

JM EPDM Peel & Stick Inside/Outside Corners consist of 60 mil thick (1.5 mm) uncured flashing with a pre-applied peel and stick tape.

JM EPDM Peel and Stick Pipe Boots

JM EPDM Peel & Stick Pipe Boots speed the flashing installation process and improve the quality of flashings on JM EPDM roofing systems. The pipe boots are specifically designed for round, roof penetrations eliminating the need for field-fabrication. The large double-thick molded ribs, at the top of each step, offer superior tear resistance as well as a cutting guide.

JM EPDM Peel & Stick Pipe Boots are formulated to provide high initial strength in both peel and shear at typical rooftop temperatures.

JM EPDM Peel and Stick Pourable Sealer Pockets

JM EPDM Pourable Sealer Pockets are one-piece, prefabricated units with a

2 1/2" (6.4 cm) wide base flange. Each pocket has a pre-applied pressure sensitive tape on the bottom of the base flange. This provides quick installation and excellent uniform bonding to the membrane.

Use to seal difficult-to-flash penetrations through the membrane.

JM EPDM Peel and Stick Sealing Strip

JM EPDM Peel & Stick Sealing Strip is a cured, 6" (15.24 cm), 9" (22.86 cm) or 12" (30.48 cm) wide, EPDM (ethylene propylene diene monomer) strip with a matte finish and factory laminated, self-adhering seam tape. This product is formulated to 1) provide high initial strength in both peel and shear at typical rooftop temperatures, 2) improve the speed of application, and 3) improve the quality and performance of the lap on JM EPDM roofing systems.

JM EPDM Peel and Stick T-Joint Patch

JM EPDM Peel & Stick T-Joint Patches are 6" (15.24 cm) round, uncured EPDM (ethylene propylene diene monomer) sheets with a factory laminated, self-adhering EPDM/butyl tape. This product is formulated to 1) provide high initial strength in both peel and shear at typical rooftop temperatures and 2) improve the speed and quality of field seaming on JM EPDM roofing systems.

JM EPDM Peel and Stick Walkpads

JM EPDM Peel & Stick Walkpads are a safe, simple, economical solution to protect roofs from damaging foot traffic. These heavy-duty, solid rubber pads are designed for the roofing industry. The nonporous surface is not affected by freeze/thaw conditions and stays in place when attached to the roof. Walkpads can be used on new or existing roofs. They provide a safe, stable and maintenance-free walkway for quick and easy access to rooftop equipment in high traffic areas.

JM EPDM Pre-Taped Curb Flashing

JM EPDM Pre-Taped Curb Flashing is produced with 60 mil (1.52 mm) thick, EPDM with a release liner and a 3" or 6" factory laminated, self-adhering EPDM tape to efficiently flash curbs with a consistent, clean appearance.

JM EPDM Protective Stone Mat

JM EPDM Protective Stone Mat is a nominal 7.0 oz/yd2 (237.34 g/m2) UV-resistant, polypropylene, needle-punched fabric.

Use the JM EPDM Protective Stone Mat as a slipsheet between the membrane and the ballast or pavers.

JM EPDM Reinforced Termination Strip with Tape

JM EPDM Reinforced Termination Strip (RTS) With Tape is a black, 6" (15.24 cm) wide, 45 mil (1.14 mm) thick, polyester scrim reinforced, cured EPDM strip with a factory-laminated, 3" (7.62 cm) self-adhering seam tape.

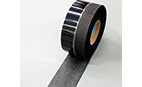

JM EPDM Seam Tape Plus

JM EPDM Seam Tape Plus is a 3" or 6" (7.62 cm or 15.24 cm) wide, self-adhering, extruded EPDM (ethylene propylene diene monomer) splice tape providing superior adhesion between EPDM sheets. This product is formulated to improve the speed and quality of lap seaming on JM EPDM roof systems. Each box of JM EPDM Seam Tape Plus includes scrubber pads and handle for seam priming.

JM Polyester Mat Protection Slipsheet

Use: JM Polyester Mat Protection Slipsheet is intended for use as a separation layer between extruded polystyrene insulation and roofing membrane in protected membrane (inverted) roof assemblies, as well as a separating sheet in some recover systems. It is also used as a protective layer between pavers and JM single ply membrane.

Material: 9.0 oz/yd2 (305.15 g/m2 ) needle-punched, UV-resistant polyester fabric.

Color: White

JM Single Ply Safety Strip

Use: Provides a visual and physical safety warning on roof top areas of caution and potential hazards including designation of the roof perimeter.

Material: 55 mil (1.40 mm) total thickness, comprised of 30 mil (0.76 mm) yellow non-reinforced TPO membrane laminated to 25 mil (0.64 mm) white cured seaming tape.

Colors: Yellow

Membrane Battens

Polymer Batten Strips are 1" (2.54 cm) wide, approximately .050" (1.27 mm) thick, plastic strips, prepunched 6" (15.24 cm) on center.

Anchor Bars are 1" (2.54 cm) wide, prepunched and counter-sunk, Galvalume®*-coated steel strips.

Use: Single Ply Membranes

Materials: Battens - Polymer

Anchor Bars - Galvalume-Coated Steel

Color: Battens - White

Anchor Bars - Grey

Deck Types: Steel, Wood and Structural Concrete

* Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers.

JM All Season Sprayable Bonding Adhesive, Accessories, and Flush

Canister

Use: JM All Season Sprayable Bonding Adhesive is an aerosol bonding adhesive that can be used for TPO and EPDM adhered roofing systems and wall flashings. The JM All Season adhesive complies to Low VOC requirements and is a contact adhesive requiring two-sided application.

Type: Two-sided sprayable aerosol adhesive for both warm and cold weather applications with fast drying properties in a pressurized canister.

Substrates: Compatible with the following field and wall applications/boards/substrates: Polyisocyanurate; Invinsa Roof Board; ProtectoR HD board; gypsum; concrete; treated plywood, cement board.

Color: Light Green

Accessories: The JM All Season Sprayable Bonding Adhesive Accessories are for use with the JM All Season Sprayable Bonding Adhesive in approved EPDM and TPO roofing systems. These accessories include the hoses, applicator, extended applicators, and nozzles necessary to use with the partner adhesive.

Flush

Use: To clean the JM All Season Sprayable Bonding Adhesive accessories including hoses, applicators, extender, and nozzles for temporary or long-term storage. Also to clean and remove over spray of the JM All Season Sprayable Bonding adhesive from membrane seams or necessary areas.

Type: A low-VOC aerosol sprayable cleaner

Installation Guides

Videos

JM EPDM Tape Primer Plus

Use: To prime JM EPDM membrane surfaces for adhering JM EPDM Tape and Peel and Stick products.

Type: One-part, solvent-based membrane primer.

Color: Translucent Electric Blue

Features: Tack-Back functionality for detail work in vertical applications and seam work in horizontal applications.

Brochures

JM EPDM Tape Primer Plus (Low VOC)

Use: To prime JM EPDM membrane surfaces for adhering JM EPDM Tape and Peel and Stick products.

Type: One-part, solvent-based membrane primer.

Color: Grey

Brochures

JM EPDM Water Based Membrane Adhesive

Use: For adhering JM EPDM membrane to approved roofing substrates. Limited availability from October 1st to April 15th.

See Bulletin T18-002, dated September 18, 2015 for additional information.

Type: One-part, water-based membrane adhesive, one or two-sided application.

Substrates: Compatible with approved insulations and cover boards; wood or concrete substrates.

Color: White

JM EPDM/PVC Pourable Sealer

Use: JM EPDM/PVC Pourable Sealer is used as a penetration pocket filler.

Type: Two-part polyurethane sealant.

Colors: Part A: Black / Part B: Amber

JM LVOC Membrane Adhesive - TPO and EPDM

Use: For adhering JM TPO and JM EPDM membranes to approved substrates. Do not use on fleece-backed membranes at any time.

Type: One-part, low VOC synthetic polymer-based membrane adhesive.

Substrates: Compatible with approved insulations and cover boards, wood substrates, concrete, and light-weight concrete decks.

Color: Yellow

Installation Guides

JM Membrane Bonding Adhesive - TPO and EPDM

Use: For adhering JM TPO and EPDM membranes to approved substrates. Do not use on fleece-backed membranes.

Type: One-part, synthetic polymer-based membrane adhesive, two-sided application.

Substrates: Compatible with insulation boards; metal, wood and other decking materials.

Color: Yellow

Installation Guides

Considerations

JM One-Step Foamable Adhesive

Use: JM One-Step Foamable Adhesive is a two-component polyurethane adhesive used for attaching insulation or cover boards to the roof deck or to other insulation boards.

Type: Two-part, cold application insulation adhesive.

Substrates: Compatible with the following insulations, cover boards, and substrates1 : polyisocyanurate; HD wood fiber; perlite; Invinsa® Roof Board; gypsum; concrete2

(Lightweight structural, poured-in-place structural, precast, and insulating); treated plywood (5/8" [1.58 cm] min. thickness); cementitious wood fiber plank; base sheets; gypsum; and some existing smooth-surfaced asphalt (per inspection).

1. Ensure that all insulation boards are 4' x 4' or smaller.

2. Drying time of 28 days required

Color: Part 1 - Tan, Part 2 - Colorless

Features: Solvent free. Set boards immediately into adhesive; reduces installation time and maximizes adhesive footprint. No hoses or pumps required. Always on ratio, eliminates guesswork.

JM Roofing System Urethane Adhesive - RSUA

Use: JM Roofing System Urethane Adhesive is a two-component polyurethane adhesive used for attaching fleece-backed single ply membranes to insulation boards or various deck types as well as insulation boards to the roof deck or to other insulation boards.

Type: Two-part, cold application insulation adhesive.

Substrates: Compatible with the following insulations, cover boards, and substrates1 : polyisocyanurate; HD wood fiber; perlite; Invinsa® Roof Board; gypsum; concrete2 (Lightweight structural, poured-in-place structural, precast, and insulating); treated plywood (5/8" [1.58 cm] min. thickness); cementitious wood fiber; gypsum; smooth or granulated BUR, APP or SBS.

1. Ensure that all insulation boards are 4' x 4' or smaller.

2. Ensure that the concrete is adequately dry for adhesion.

Color: Part 1 - Tan, Part 2 - Colorless

Features: Solvent free, and HCFC or CFC free. Universal adhesive for adhering fleece-backed membranes and insulation boards. Sets in minutes.

Installation Guides

Installation Instructions for JM Roofing Systems Urethane Adhesive (RSUA)

JM Single Ply LVOC Caulk

Use: To seal the edges around flashing terminations, peel and stick products and exposed edges of JM membrane cement splices.

Type: One-part, elastomeric sealant.

Colors: Black or White

JM Single Ply Membrane Primer - Low VOC

Use: To prime JM EPDM and TPO membrane surfaces for adhering EPDM or TPO peel and stick products.

Type: One-part, low VOC synthetic polymer-based membrane primer.

Color: Clear to Light Yellow

JM Single Ply Sealing Mastic

Use: To seal JM Single Ply membranes to terminations and other penetrations.

Type: One-part, butyl polymer-based water cutoff mastic.

Substrates: Compatible with wood, concrete, metal, plastic, and other substrates for water penetration prevention.

Color: Grey

JM Weathered Membrane Cleaner

Use: To thoroughly clean the release agent and dirt from JM TPO and JM EPDM membranes prior to applying primers or splice adhesives.

Type: One-part, organic solvent cleaning agent.

Color: Clear

One-Part Pourable Sealer

Use: JM One-Part Pourable Sealer is used as a penetration pocket filler.

Type: One-part polyether sealant.

Color: Grey

Brochures

Installation Guides

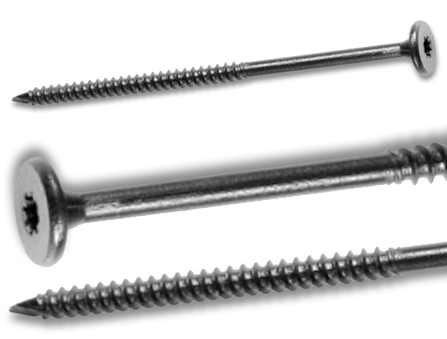

All-Purpose Fasteners

All Purpose Fasteners are #14 case-hardened steel fasteners with a #3 Phillips head. The point is designed for quick installation in new or re-roof applications.

Use: Membranes and Insulation

Material: Case-hardened steel

Gauge: #14

Head: #3 Phillips head

Color: Grey

Deck Types: Wood, Concrete, and 18 - 24 gauge (1.25 mm - 0.56 mm) Metal.

Plate Compatibility*

• UltraFast® Locking Plastic Plates

• UltraFast® Metal Plates

• High Load Plates (not pictured)

• APB Plates (not pictured)

• RhinoPlate (concrete decks)

* See corresponding data sheets for information regarding UltraFast, High Load, and APB Plates.

APB Plates - Membrane Fastening Plate

APB Plates are made of Galvalume®*-coated steel. The 2" (51 mm) round plate with barbs provides an even distribution of loads and eliminates sharp corners that can damage the insulation or membrane.

Use: EPDM Membranes

Material: Galvalume-Coated Steel

Plate: 2" (5.1 cm) round

Color: Grey

Deck Types: Wood, Concrete, and 18 - 24 gauge (1.25 mm - 0.56 mm) Metal.

* Galvalume is a registered trademark of BIEC International, Inc. and some of its

licensed producers.

Fastener Compatibility

Designed to be used with Johns Manville All Purpose Fasteners and High Load Fasteners.

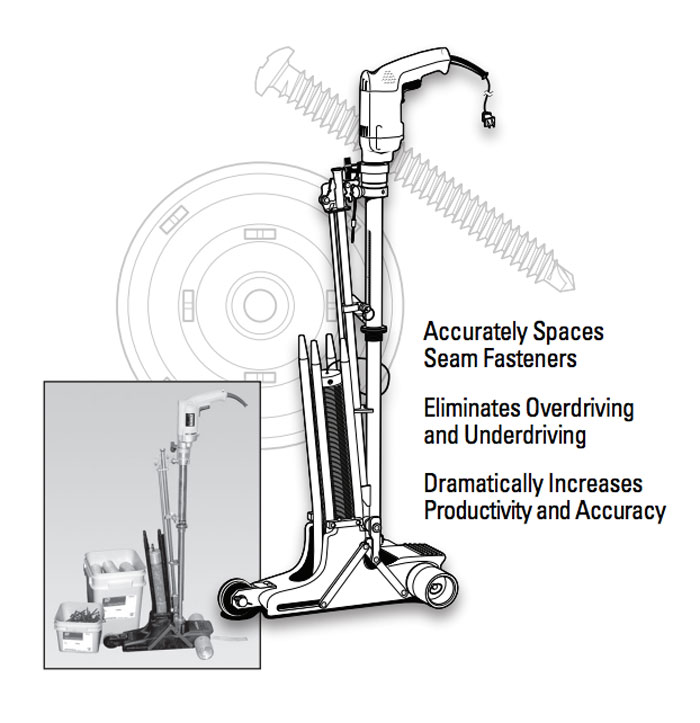

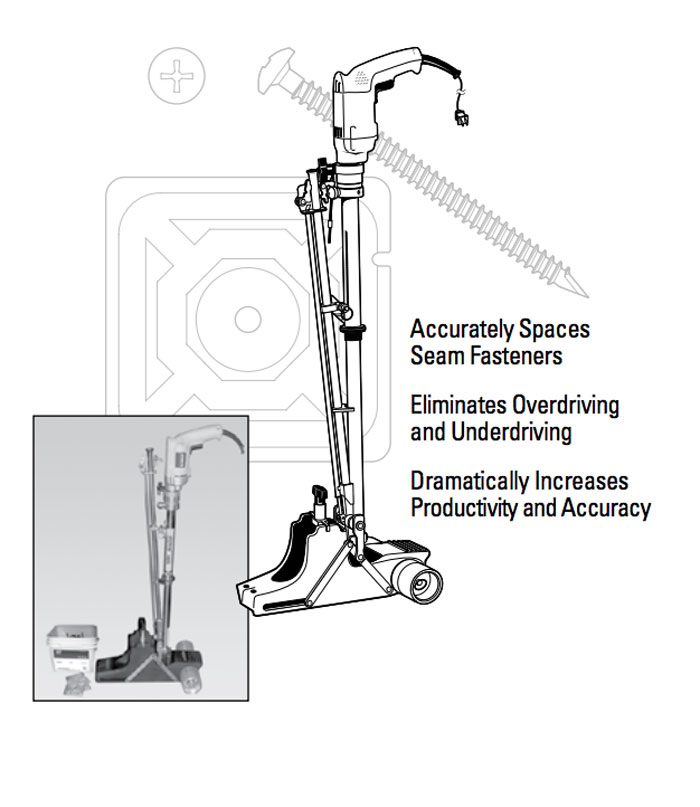

High Load AccuSeam System

The High Load AccuSeam System is a premier automated system for mechanically attached seams. The System positions the 23⁄8" (6.03 cm), round, High Load Plate with eye hooks, and installs the High Load Fastener, up to 6" (15.24 cm) in length in a one-step, continuous process. Standard High Load Plates are not compatible with the AccuSeam Fastener and Plate System.

Use: Membranes

Material: High Load Fastener - Case-hardened steel

High Load AccuSeam Plate - Galvalume®*-Coated Steel

Gauge: #15

Head: #3 Phillips head

Plate: 23⁄8" (6.03 cm) round

Color: Blue (fasteners), Grey (plates)

Deck Type: Wood or 18 - 24 gauge (1.25 mm - 0.56 mm) Metal.

* Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers.

High Load Fasteners (Pre-Assembled)

.jpg_%3b%20filename_%3dutf-8%27%27high-load-fasteners-%2528pre-assembled%2529.jpg)

High Load Fasteners are #15 fasteners with a #3 Phillips head. The point is designed for quick installation in new and re-roof applications. High Load Fasteners are pre-assembled with FM Global® approved High Load Plates.

High Load Plates are 23⁄8" (6.03 cm) round, 20-gauge (0.9 mm) Galvalume®*-coated steel discs.

Use: Membranes

Material: High Load Fastener - Case-hardened steel

High Load Plate - Galvalume-Coated Steel

Gauge: #15

Head: #3 Phillips head

Plate: 23⁄8" (6.03 cm) round

Color: Blue (fasteners), Grey (plates)

Deck Type: Wood or 18 - 24 gauge (1.25 mm - 0.56 mm) Metal.

* Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers.

High Load Fasteners and Plates

.jpg_%3b%20filename_%3dutf-8%27%27high-load-fasteners-%2528pre-assembled%2529.jpg)

High Load Plates are heavy duty, Galvalume®*-coated steel seam plates with eye hooks.

High Load Plus Plates are heavy duty, Galvalume-coated steel seam plates with barbs.

Use: Membranes

Material: Galvalume-Coated Steel

Gauge: 20-Gauge Steel

Size: High Load Plate - 2 3⁄8" (6.03 cm) round

High Load Plus Plate - 2 3/4” (6.99 cm) round

JM 90 Seam Plate - 3" (7.62 cm) round

Color: Grey (Galvalume-coated steel)

JM Purlin Fastener

The JM Purlin Fastener is a steel-coated fastener with a ¼" hex head and ¾" (19 mm) drill point. The drill point allows the fastener to be drilled through the purlin before the threads engage into the standing seam metal roof.

Use: Membranes

Material: Steel Coated Fasteners

Gauge: #12 Head: ¼" Hex Head

Plate: 23⁄8" (6.03 cm) round

Color: Grey

Deck Type: Structural Steel Purlins 12 - 18 gauge (2.77 mm - 1.25 mm) Metal.

JM Termination

Termination Bars are 1.34" (3.4 cm) wide, extruded, pre-punched aluminum strips.

Anchor Discs are 2" (5.1 cm) diameter, round, Galvalume®*-coated steel discs.

Masonry Nail-In Anchors are one-piece zinc anchors designed for fastening to concrete or masonry walls.

Use: Membranes

Materials:

High Load Fasteners - Corrosion-Resistant Steel

Zinc Nail-In Anchors - Zinc-Coated Steel

Anchor Discs - Galvalume

Termination Bars - Extruded Aluminum

Color: Various

Deck Types: High Load Fasteners - Wood and 18-24 Gauge Metal Zinc Nail-In Anchors - Concrete and Masonry

*Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers.

Lite-Deck Fasteners and Plates

Lite-Deck Fasteners are available in lengths from 2 5/8” to 12" (67 mm to 305 mm), come with a square drive and offer coarse thread to provide high pullout resistance.

Lite-Deck plates are 3" (76 mm) round, Galvalume®*-coated plates for use with Lite-Deck Fasteners.

Use: Insulation

Fastener: Steel

Head: #3 Square Drive

Plate: 3" (76 mm) Galvalume-Coated Steel - Round

Color: Black (fasteners) Grey (plates)

Deck Type: Gypsum, and Cementitious Wood Fiber

* Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers.

Nail-Lok SD

Nail-Lok SD is utilized with steel decks in several panel applications including Nailboard, Vented Nailboard, structural insulated panels (SIP), and prefabricated wall panels. The extra-large star/spider head increases pull-through resistance and eliminates the need for plates or washers.

Use: Nailboard and Vented Nailboard Fastener.

Material: 10B21 steel with a corrosion-resistant coating.

Shank: 0.190” diameter Head: 0.625” diameter star/spider drive (free drive bits in each bucket).

Point: Spade

Color: Black Deck Types: 18-24 gauge steel

Structural Concrete (Predrilling is required with a pilot at least ½” deeper than fastener embedment. Pilot hole size varies, perform a pull-test to determine proper drill bit size).

Nail-Lok WD

Nail-Lok WD is utilized with wood decks in several panel applications including Nailboard, Vented Nailboard, structural insulated panels (SIP), and prefabricated wall panels. The extra-large star/spider head increases pull-through resistance and eliminates the need for plates or washers.

Use: Nailboard and Vented Nailboard Fastener.

Material: 10B21 steel with a corrosion-resistant coating.

Shank: 0.190” diameter

Head: 0.625” diameter star/spider drive (Free drive bits in each bucket).

Point: Gimlet

Color: Black Deck Type: Wood

Polymer Auger Fasteners

Polymer Auger Fasteners are glass-reinforced nylon fasteners with an internal ¼" (6 mm) square drive. Polymer Auger Fasteners have a 1" (2.5 cm) diameter head.

Polymer Auger Fasteners are available with Galvalume®*-coated, metal stress plates, designed to lock into the fastener head.

Use: Insulation and Membranes

Material: Fasteners - Polymer

Plates - Galvalume-Coated Steel

Gauge: 0.675" Diameter Screw

Head: 1" (2.5 cm) Diameter, ¼" (6 mm) Square Drive

Plates: 2" (5.1 cm) or 3" (7.6 cm) Round

Color: Black (fasteners), Grey (plates)

Deck Types: Cementitious Wood Fiber or Gypsum

* Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers.

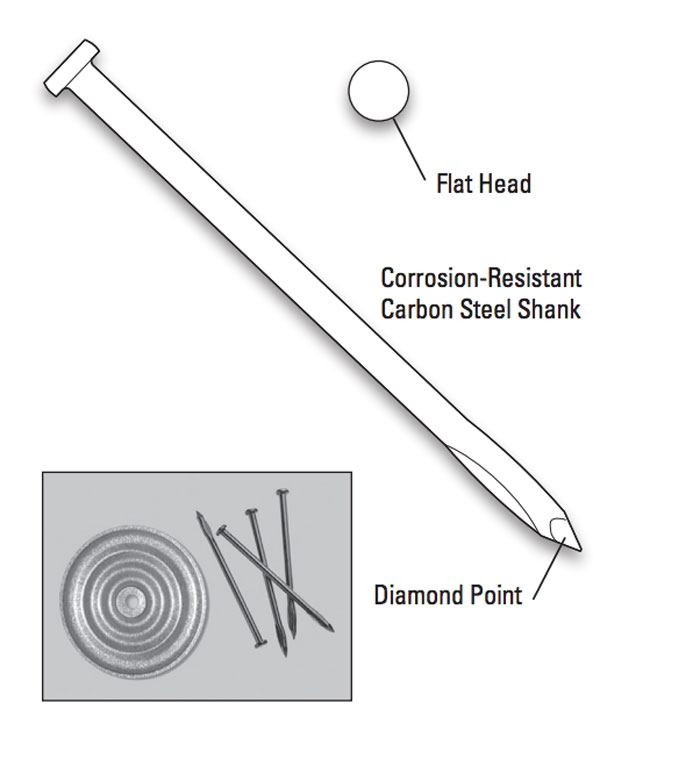

Structural Concrete Deck Fasteners and Plates

Structural Concrete Deck Fasteners are diamond point, non-threaded fasteners for hammer-in installation of insulation and single ply membranes to structural concrete. These carbon steel fasteners have a corrosion-resistant coating.

Use: Insulation and Membranes

Material: Diamond Point, Corrosion-Resistant Coated Carbon Steel

Head: Flat

Color: Black

Deck Type: Structural Concrete

Plate Compatibility*

- UltraFast® Flat-Bottom, Metal Plates

- APB Plates

- High Load Plates

* See corresponding data sheets for information regarding UltraFast, APB and High Load Plates.

UltraFast AccuTrac Fastener and Plate System

The UltraFast AccuTrac Fastener and Plate System utilizes the standard UltraFast Fastener and the UltraFast Accutrac, recessed or flat bottomed, square plate. The AccuTrac tool positions the plate and installs fasteners 15⁄8" - 6" (4.13 cm - 15.24 cm) in a one-step process. Consistent vertical alignment of fasteners ensures maximum thread engagement and pullout performance.

Use: Membranes

Material: Fasteners - Case-Hardened Steel

Plates - Galvalume®*-Coated Steel

Gauge: #12

Head: #3 Phillips Head

Plate: UltraFast AccuTrac™ - 3" (7.62 cm) Square**

Color: Blue (fasteners), Grey (plates)

Deck Type: Wood or 18 - 24 gauge (1.25 mm - 0.51 mm) Metal.

*Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers.

**Standard UltraFast Plates are not compatible with this system.

UltraFast Fasteners and Plates

The UltraFast Fastener is a #12, case-hardened steel, polymer-coated fastener with a buttress thread design that provides maximum pullout values and minimizes fastener backout. Available with either a #3

Phillips head or a ¼" (6.35 mm) hex head. The drill point is designed for quick installation in new or re-roof applications, and provides exceptional drilling capability in higher tensile decks.

Use: Insulation

Material: Fasteners - Case-Hardened Steel, Polymer-Coated

Gauge: #12

Head: #3 Phillips Head or ¼" (6.35 mm) Hex Head

Color: Blue

Deck Types: Wood or 18 - 24 gauge (1.25 mm - 0.51 mm) Metal

UltraFast Locking Plastic Plates are 3” (7.62 cm) round, high strength polypropylene plates with a special locking feature.

UltraFast Metal Plates are 3” (7.62 mm) round or square, premium Galvalume®*-coated steel metal plates.

Use: Insulation

Material: Plates - Galvalume-Coated Steel or High Strength Polypropylene

Gauge: 26 Gauge Steel

Plates: 3" (7.62 cm) Round Locking Plastic & Round or Square Metal

Colors: Grey (metal plates), Blue (plastic plates)

*Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers.

UltraFast Plus Plate

The UltraFast® Plus Plate is made of Galvalume®*-coated steel. The 3" (7.62 cm) nominal square plate is 0.010" (0.25 mm) thicker than the standard UltraFast square metal plate, providing a stiffer surface area to improve wind uplift performance of the system. The plate is used for fastening Invinsa® Roof Board to the roof deck in fully adhered single ply systems. The plate is designed to be used with UltraFast #12 or #14 fasteners.

Use: Cover Board

Material: Galvalume®-Coated Steel

Thickness: 0.028" (0.71 mm)

Plates: 3" (7.62 cm) nominal Square Metal

Colors: Grey (metal plates)

Deck Types: Wood or 18 - 22 gauge (1.25 mm - 0.76 mm) Metal

*Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers.

UltraFast Pre-Assembled Fasteners

The UltraFast Pre-Assembled Fastener is a #12, case-hardened steel, polymer-coated fastener with a buttress thread design that provides maximum pullout values and minimizes fastener backout.. Available with a #3 Phillips head or ¼" (6.35 mm) hex head (available by special order only). The drill point is designed for quick installation in new or re-roof applications, and provides exceptional drilling capability in higher tensile decks. The UltraFast Locking Plastic Plate prevents fastener pop-up.

Use: Insulation

Material: Fasteners - Case-Hardened Steel, Polymer-Coated

Plates - Galvalume®*-Coated Steel or Plastic

Gauge: #12

Head: #3 Phillips Head (¼" (6.35 mm) Hex Head is available by special order only)

Plates: 3" (7.62 cm) Round Locking Plastic or Round Metal

Colors: Blue (fasteners), Grey (metal plates), Blue (plastic plates)

Deck Types: Wood or 18 - 24 gauge (1.25 mm - 0.56 mm) Metal.

* Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers.

UltraLok Locking Impact Fastener

UltraLok Locking Impact Fasteners and Plates consist of a preassembled Galvanized steel tube, a 2.7" (6.86 cm) Galvalume®*-coated steel disc, and a precision-formed, coated- steel, high tensile, wirelocking staple. The disc is securely clamped to the tube and is rib-reinforced to resist cupping.

Use: Cover Boards and Base Sheets

Material: Tube - Galvanized Steel

Plates - Galvalume-Coated Steel

Locking Staple - Coated-Steel, High Tensile Wire

Plate: 2.7" (6.86 cm) Metal - Round

Color: Grey

Deck Types: Poured Gypsum, Cementitious Wood Fiber and LWIC Lightweight Insulating Concrete

* Galvalume is a registered trademark of BIEC International, Inc. and some of its licensed producers

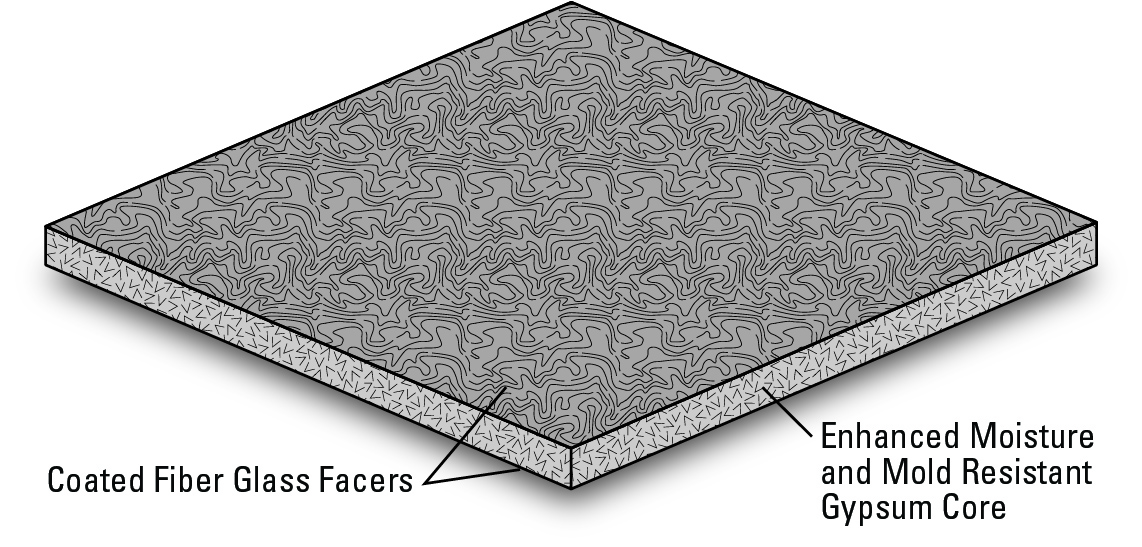

DensDeck Prime Roof Board

Meets the requirements of ASTM C 1177

Enhanced Face Mat: Coated fiberglass facer ideal for fully adhered systems provides a broader compatibility and higher performance with roofing adhesives.

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

DensDeck Roof Board

Meets the requirements of ASTM C 1177

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Moisture and Mold Resistance: Scores a 10, the highest performance level for mold resistance, when tested in accordance with ASTM D 3273.

DensDeck StormX Prime Roof Board

Meets the requirements of ASTM C 1177

Very Severe Hail: Achieves FM 'VSH' approval with adhered 60 or 80 mil (smooth back) JM TPO membrane and standard JM TPO membrane adhesives when 4'x4' panels are adhered in low rise foam adhesive ribbons, 12" O.C. min.

Enhanced Face Mat: Coated fiberglass facer ideal for fully adhered systems provides a broader compatibility and higher performance with roofing adhesives.

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Brochures

DEXcell Cement Roof Board

Meets the requirements of ASTM C 1325

Durability: Composed of a lightweight cementicious core to provide exceptional impact resistance.

Strength: Exceptionally high compressive strength improves overall roof system performance. Cement board is able to withstand prolonged exposure to moisture and is ideal for systems where wind uplift and puncture resistance are a concern.

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics.

Moisture and Mold Resistance: Cement based core provides superior moisture, mold, and mildew resistance. Scores a maximum "10" for mold resistance when tested per ASTM D 3273.

DEXcell FA Glass-Mat Roof Board

Meets the requirements of ASTM C 1177

Handleability: Heavy duty coated fiberglass facer ideal for fully adhered systems improves handling and strength. Scores and snaps easily.

Strength: High compressive strength improves overall roof system performance. Ideal for systems where wind uplift and puncture resistance are a concern.

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Moisture and Mold Resistance: Enhanced mold resistant core and coated fiberglass facers provide mold and mildew resistance per ASTM-D 3273.

DEXcell Glass-Mat Roof Board

Meets the requirements of ASTM C 1177

Handleability: Coated fiberglass facer ideal for mechanically fastened systems improves handling and strength. Scores and snaps easily.

Fire Performance: FM Class 1 for fire barrier requirements and UL Class A unlimited slope with excellent surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Moisture and Mold Resistance: Enhanced mold resistant core and coated fiberglass facers provide mold and mildew resistance per ASTM-D 3273.

ENRGY 3 - Flat and Tapered

Meets the following requirements:

ENRGY 3 / Tapered ENRGY 3

• CAN/ULC S704, Type 2, Class 3 (140 kPa)

• ASTM C 1289, Type II, Class 1, Grade 2 ENRGY 3 25 PSI / Tapered

ENRGY 3 25 PSI

• CAN/ULC S704, Type 3, Class 3 (170 kPa)

• ASTM C 1289, Type II, Class 1, Grade 3

Glass-Reinforced Facers: Provides rigidity and resistance to indentation and crushing, and are compatible with BUR, modified bitumen and single ply membrane systems.

Closed Cell Polyisocyanurate Foam Core: Provides high R-value per inch in built-up, modified bitumen, metal roof and single ply roof systems, and utilizes a zero ozone depletion blowing agent that provides high thermal insulation performance.

Resources

ENRGY 3 CGF - Flat and Tapered

Meets the following requirements:

ENRGY 3 CGF / Tapered ENRGY 3 CGF

• CAN/ULC S704, Type 2, Class 3 (140 kPa)

• ASTM C 1289, Type II, Class 2, Grade 2

ENRGY 3 25 PSI CGF / Tapered ENRGY 3 25 PSI CGF

• CAN/ULC S704, Type 3, Class 3 (170 kPa)

• ASTM C 1289, Type II, Class 2, Grade 3

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in fully adhered single ply systems.

Closed Cell Polyisocyanurate Foam Core: Provides high R-value per inch in built-up, modified bitumen, metal roof and single ply roof systems, and utilizes an environmentally compliant blowing agent that provides high thermal insulation performance.

Invinsa

Meets the requirements of ASTM C 1289, Type II, Class 4, Grades 1, 2 and 3

High-Density Polyisocyanurate Foam Core: Closed cell polyisocyanurate foam technology provides additional insulation value, with lightweight and low water absorption characteristics.

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in fully adhered single ply systems.

Lightweight: Offers labor and installation efficiencies and allows more options for situations where the overall weight is a concern. This also means easy hoisting, staging and maneuvering around the roof.

Flexibility: Means less breakage during handling, and in re-cover applications it allows Invinsa to accommodate minor irregularities in existing roofs.

User Friendly: Invinsa allows easy & efficient scoring, cutting and snapping which permits fast, tight fabrication and all in a low dust environment.

Resistance To Damage: High impact, flexural and compressive strength provides a protective layer for insulation while working with the membrane above to ensure maximum performance and longevity

Brochures

Invinsa Product Line Brochure

Single Ply Roofing for Metal Roof Retrofit

JM Polyiso Cover Boards Brochure

Case Studies

Basalt Elementary - Reaping Rewards for using Invinsa and EPDM at High Altitudes

Shearer's Foods – LEED Platinum PVC Roof for Snack Food Manufacturer

McLane Western Case Study - JM TPO system protects high-volume, fast-turn business of perishables

Tower One / Colorado Plaza Towers Case Study

Biltmore House – PVC Protects Historic Treasures

Nailboard

Meets the requirements of ASTM C 1289, Type V

(available with 20 or 25 psi ENRGY 3®)

Oriented Strand Board (OSB): Provides a strong nailable surface; always install wood side up. Available wood thickness standard 7 ⁄16" or 5 ⁄8" thick rated "1 OSB". Wood edges are routed 1 ⁄8" to allow for expansion and contraction of the wood.

ENRGY 3: Closed cell polyisocyanurate foam core bonded inline to the wood base on one side and a glass-reinforced facer on the other. Nailboard can also be manufactured off-line using an adhesive between the wood and ENRGY 3.

Brochures

ProtectoR Foam

Meets the following requirements:

- High-Density layer meets the requirements of ASTM C 1289, Type II, Class 4, Grade 1

- Standard-Density layer meets the requirements of ASTM C 1289, Type II, Class 2

- Currently no ASTM designation for this composite.

High-Density ProtectoR HD: Provides a high compressive strength protective layer for insulation while working with the membrane above to ensure maximum performance and longevity.

Standard-Density Foam (ENRGY 3 CGF): Closed cell polyisocyanurate foam manufactured inline to create a homogeneous board with ProtectoR HD and coated glass facers.

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in fully adhered single ply systems.

Cost Savings: Installation labor savings by combining cover board and insulation into a single board. Eliminates adhesive cost to adhere cover board to insulation.

ProtectoR HD

Meets the requirements of ASTM C 1289, Type II, Class 4, Grade 1

High-Density Polyisocyanurate Foam Core: Closed cell polyisocyanurate foam technology provides additional insulation value (R-value of 2.5), with lightweight and low water absorption characteristics.

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in adhered single ply systems.

Lightweight: Offers labor and installation efficiencies and allows more options for situations where the overall weight is a concern. This also means easy hoisting, staging and maneuvering around the roof.

High R-Value (2.5 R): Provides significantly more thermal insulation (R-value) than wood fiber or gypsum boards.

User Friendly: ProtectoR HD allows easy & efficient scoring, cutting and snapping which permits fast, tight fabrication and all in a low dust environment.

Resistance To Damage: High impact, flexural and compressive strength pro- vides a protective layer for insulation while working with the membrane above to ensure maximum performance and longevity.

Up to 50% Fewer Fasteners: Achieves FM 1-90 utilizing 8 fasteners per 4'x8'boardwithanadhered reinforcedmembraneand11fastenersper 4'x 8' board with an adhered non-reinforced membrane over a min. 22 ga steel deckorstructuralconcretedeck.

RetroPlus Roof Board

Meets the requirements of ASTM C 728, Type 3

TopLoc® Coating: Top surface is sealed with this special coating to reduce excessive adhesive absorption in hot-asphalt and cold applied roofing systems, and to provide a strong surface for bonding bituminous membranes.

Expanded Perlite: Provides good dimensional stability, excellent insulation value with stable R-value and superior fire resistance.

Reinforcing Cellulosic Fibers: Consists of recycled newsprint to provide strength to the board as well as high recycled content. JM utilizes third party certification by UL environment to certify the recycled content and contributes to the LEED Materials and Resource (MR) credit 4.

High Density: Provides additional strength and durability over 1/2" Retro-Fit Board with low moisture content and water resistance compared to wood fiber board.

Brochures

Recycled Content

SECUROCK Cement Roof Board

Meets the requirements of ASTM C 1325

Ideal for liquid applied membrane roof systems.

Strength: Engineered to provide superior wind-uplift performance for a wide variety of roof assemblies. The board is formed using an aggregated portland cement slurry with a polymer-coated, glass-fiber mesh completely encompassing edges and both surfaces, to enhance bond strength of membrane systems and gives excellent resistance to delamination.

Fire Performance: Provides excellent fire performance with unlimited slope classifications and is non-combustable per UL 790.

Moisture and Mold Resistance: Cement based, highly water durable board, scored a maximum "10" for mold resistance when tested per ASTM D 3273.

SECUROCK Ultralight Glass-Mat Roof Board

Meets the requirements of ASTM C 1177

Handleability: Unmatched mat-to-core tensile bond strength, easy to cut and has reduced facer delamination.

Fire Performance: Provides excellent fire performance, and demonstrates exceptional surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Moisture and Mold Resistance: Fiber glass facer and back with treated core delivers moisture and mildew resistance.

SECUROCK Gypsum-Fiber Roof Board

Meets the requirements of ASTM C 1278

Strength: Engineered to provide high wind-uplift performance. Uniform composition providing enhanced bond strength of membrane systems with no risk of facer delamination.

Fire Performance: Provides excellent fire performance, and demonstrates exceptional surface burning characteristics. 5/8" thickness meets the requirements of Type X per ASTM C 1177.

Moisture and Mold Resistance: Integral water-resistant core scored a maximum "10" for mold resistance when tested per ASTM D 3273.

SeparatoR

Meets the requirements of ASTM C 1289, Type II, Class 1, Grade 2

Closed Cell Polyisocyanurate Foam Core: Provides high R-value per inch, light weight, and flexibility in recover and metal retrofit applications.

Glass-Reinforced Facers: Provides rigidity and resistance to indentation and crushing for mechanically fastened single ply membrane systems.

High R-Value (2.8 R): ½" SeparatoR Board has more than two times the R-value of wood fiber or gypsum boards.

Brochures

SeparatoR CGF

Meets the requirements of ASTM C 1289, Type II, Class 2, Grade 3

Closed Cell Polyisocyanurate Foam Core: Closed cell polyisocyanurate foam technology provides additional insulation value with lightweight and low water absorption characteristics.

Inorganic Coated Glass Facers: (With no cellulose) Provide improved resistance to mold growth, as well as a smooth surface that performs well with self-adhering systems, and efficient adhesive application in adhered single ply systems.

High R-Value (2.9 R): Has more than two times the R-value of wood fiber and more than four times the R-value of gypsum boards.

User Friendly: Allows easy and efficient scoring, cutting and snapping which permits fast, tight fabrication and all in a low dust environment.

Lightweight: Offers labor and installation efficiencies and allows more options for situations where the overall weight is a concern. This also means easy hoisting, staging and maneuvering around the roof.

Up to 50% Fewer Fasteners: Achieves FM 1-90 utilizing 8 fasteners per 4'x8'boardwithanadhered reinforcedmembraneand11fastnersper 4'x 8' board with an adhered non-reinforced membrane over a min. 22 ga steel deckorstructuralconcretedeck.